“Perfection is achieved, not when there is nothing more to add, but when there is nothing left to take away.” – Antoine de Saint-Expuéry, Airman’s Odyssey

Background

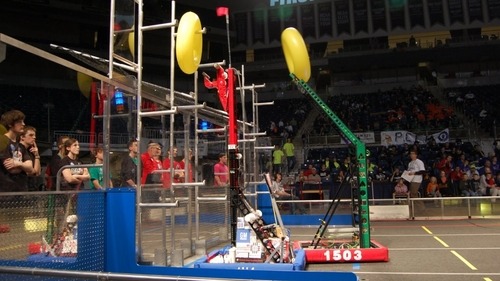

FIRST Team 1503, Spartonics, from Niagara Falls, Ontario, Canada had a disastrous run during the 2010 FIRST Robotics Competition season. While we did make it to the semi-finals at both of their regional events, we were the weakest robot on the alliance each time. Team 1503 failed to make the eliminations at the FIRST Championship that April. We built a robot that was hideous, underperformed and overall had poor build quality. Truthfully, the team had a disappointing season because we tried to build outside of our means. We did not have the capability to divide up the team enough to design a reliable drive base, an effective kicker, a good ball control system and a hanging system. We simply did not have the manpower to ensure that each subsystem would work efficiently and well with the others. The 1503 Breakaway robot ended up being a hap-hazard built machine that was an eyesore every time it took to the field. While it was a trying year for many teams, Team 1503’s 2010 season was a far cry from their 2006 season that included three regional wins and an appearance in the divisional eliminations at the FIRST Championship. It was so bad, that I will not post a photo of it in this article.

The Game

Fast forward to 2011, Spartonics were determined to redeem themselves from an embarrassing showing the prior season. We started the season with one goal in mind; stay within our means. We decided to go about this by building the simplest robot possible that could be competitive in the finals of most regional events.

The game was relatively simple. Logomotion was a game where teams had to design robots to score inflatable tubes shaped like the elements of the FIRST logo – a triangle, circle and a square. Teams earned bonus points if they were arranged in the correct order to reflect the FIRST logo, and also via special “Ubertubes” that were scored in the autonomous period. The tube scoring for Logomotion is outlined below:

Autonomous Period:

- Not HANGING 0 Points

- HANGING on bottom row: 2 Points

- HANGING on middle row: 4 Points

- HANGING on top row: 6 Points

Tele-operated Period: LOGO PIECE: ALONE / Over UBERTUBE

- Not HANGING: 0 Points / 0 Points

- HANGING on bottom row: 1 Points / 2 Points

- HANGING on middle row: 2 Points / 4 Points

- HANGING on top row: 3 Points / 6 Points

*If a ROW forms the FIRST Logo, the score for that row is doubled.

Teams could also score points by deploying a separate MINIBOT onto one of four ten foot poles during the end game. The MINIBOTS were to race up the poles, with the slowest minibots receiving a diminishing return on their race score. This is outlined below:

Minibot Scoring:

- 1st MINIBOT to TRIGGER the TARGET 30 points

- 2nd MINIBOT to TRIGGER the TARGET 20 points

- 3rd MINIBOT to TRIGGER the TARGET 15 points

- 4th MINIBOT to TRIGGER the TARGET 10 points

Game Analysis

Shortly after Logomotion was released, the team dived into the game manual to read the rules and come up with a game plan. Immediately a few things were pointed out.

- It was far less valuable to score both regular tubes and Ubertubes on the lower rows of pegs.

- Ubertubes can only be scored in autonomous mode.

- Ubertubes could be a nuisance on the floor because they cannot be possessed during the Tele-operated period.

- There were no rules in place preventing teams from throwing tubes over the alliance station wall down the field.

- There were diminishing returns on the minibot race as well.

- Defense in the middle of the field could seriously hinder tube collection.

The team also created scoring models to attempt to determine what kind of scores would be seen during matches, and which chains of actions created the biggest return on points. And then the team stumbled on something.

The “Six One One Slamma Jamma Special”

During scoring analysis it was noticed that an easy strategy with a high return existed. If the robot could score one Ubertube on any of the top pegs, score six tubes on the top row to form two LOGO Bonuses, and take first or second place in the MINIBOT race, the robot was capable of scoring a minimum of 68 points and a maximum of 78 points entirely by itself. Timing analysis said that an efficient robot could score 8-9 tubes with plenty of practice and a good human player. Immediately, design proposals of elevators, roller claws, double and triple jointed arms started flying around the team. However, they all had one thing in common – they were too complicated for the team to have time to refine and iterate enough times for the robot to be competitive.

The Gamble

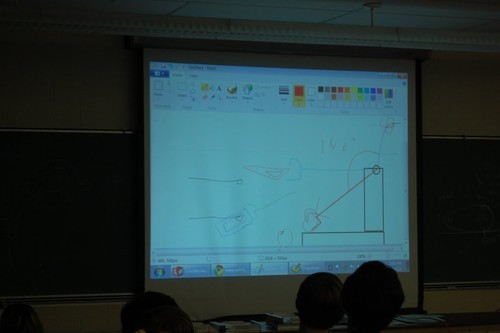

The horribly drawn sketch that led to so many great things.

One of the robots proposed was a simple single-jointed arm with a simple pneumatic tube-grabbing claw on a simple single speed 6WD chassis. This idea was to purpose build a robot to score one Ubertube in autonomous, six logo pieces in tele-operated and win the minibot race during the end game. The caveat to this proposal is that the robot would not have the ability to retrieve game pieces from the ground in order to retain simplicity. The robot would have to drive the length of the field each time to score and retrieve tubes from the human player feeder stations. Scoring simulation said it was possible. Early sketches said it was simple and cheap. Mentors like it. Students liked it.

It was a risky strategy, but it was also conceptually conservative. Early in our game analysis we felt that defense at center field would be a major issue, and early human player tosses proved that the tubes were difficult to toss. We concluded that most tubes would end up in unprotected zones in the center of the field where the robot would be vulnerable to defense, impeding its ability to retrieve tubes from the floor. So we had two options – either build a swerve drive much like the 2007 robot, or make a conscious choice to not floor load. The team deliberated this for about a week while designing the drivetrain and came to a compromise.

The robot would compete at its first regional without floor loading ability. It would need to be designed so that a second joint could be added to the existing single-jointed arm if the robot wasn’t effective enough.

The Robot: Drivetrain

Forgive the messy wiring, this was the practice robot. It was also assembled using bolts and not rivets as mentioned in the article. See? Nothing fancy here.

The team decided on a simple single-speed 6WD drivetrain utilizing AndyMark CIMple Boxes with an external reduction to give a final theoretical top speed of ~11 fps. The team elected to have a single-speed drivetrain in order to save weight and to increase overall simplicity of the robot. The chassis structure was built exclusively out of 5052 H32 1/8” aluminum sheet metal and riveted together. Additionally, the chassis was strengthened and lightened with a set of punches and forming dies in the shapes of a triangle, circle and square. Additionally, we also had a punch and forming die set to create bearing seats via making nice flange.

The Robot: The Arm and Tower

The tower and arm assembly of the robot needed to be lightweight to keep our center of gravity down low, but strong enough to take torsional and transverse shear forces from driving around with the arm in different orientations. It was to be constructed of 5052 H32 1/16” aluminum sheet metal with some aluminum angle and thin walled pipe to support the tower. The arm was designed to be super wide to ensure proper distribution of torsional stress throughout the tower, rather than creating a weak shear point at a narrow joint in the shoulder. The arm also had bearing seats sized for 1.125” OD bearings running up the sides, which would allow a folding extension for future potential floor loading ability.

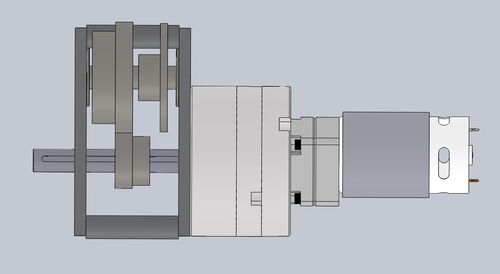

The Robot: The Frankenbox (Arm Gearbox)

This monstrosity was built out of the need to save money. We already had the GEM planetary parts in house, along with the sprockets, chain and gears. We did not have the CIM-u-lator spur reduction gearboxes, so we ordered them. The setup was a mouthful: An RS-775 mated to a CIMulator mated to three stages of GEM planetary which output into a custom gearbox for a 2:1 reduction which drove the final 18:60 sprocket reduction giving an approximate 900:1 reduction. We wanted to keep the arm slow and highly controllable, so we opted to do it mechanically with stuff we had laying around.

The Robot: Minibot (Banana!) and Deployment

The minibot deployment system on SPARDIS was pretty simple. It was meant to be reliable rather than quick, because our prototyping revealed that slamming minibots into the tower pole was both destructive and inconsistent. So our deployment system used a pneumatic cylinder paired with a cascading scissor linkage arrangement to push a shuttle with the minibot on a hardware store drawer slide to the pole. Once the minibot left the bumper perimeter, a pin that was tied to the main robot frame was pulled to turn on the minibot via a limit switch. To turn off the minibot, we relied on a 5A inline-fuse to burn out rather than a complicated switch system to turn off the minibot.

The Results

This robot is considered to be the most successful in Team 1503 history. SPARDIS went on to win two regionals, and made a semi-finals appearance on Einstein thanks to a win in the Newton division. SPARDIS ended the regular season with an overall record of 41-9-0. Not bad for a robot that was dismissed so frequently by many.

The robot was regularly an offensive juggernaut on the field, easily scoring 6-7 tubes in most matches. Because it was underweight, it was also highly maneuverable for getting around center field defense. In addition, between the Pittsburgh and Greater Toronto East Regionals, we discovered that we could in fact floor load with this robot. We utilized this to develop a two-tube autonomous, and also to pick up dropped tubes (frequently squares) in emergencies.

Here is a match that showcases our two tube autonomous mode. Mind the minibot.

Here is a full field video of it playing on Einstein. Bonus at the end.

Reception From Other Teams

The simplicity and elegance of SPARDIS was admired by other teams, but many who stopped by our pit easily dismissed the competitiveness of our machine for it’s lack of ability to floor-load. Early on in our first regional this allowed us to get in our groove and do our thing on the field. We actually improved even more while we were ‘under the radar’ because we weren’t under any scrutiny or pressure from other teams. Once our peers caught on to our average score of hanging 6 tubes a match and consistently scoring in the minibot race, teams treated us as more of a threat to play late on Saturday afternoon. We encountered a lot of the center-field defense we predicted during our brainstorming phases, but we were able to plan for and adapt to playing around it. Our average scoring output didn’t suffer.

So, Why Did It Work?

- We completed the robot.

- We completed the practice robot in week 3.

- We practiced like hell.

The simplicity of our design allowed us to move through the build phase extremely quickly. We were scoring tubes during week 3 of the build season with our practice robot. This was two weeks earlier than we had ever finished the practice robot, and it gave us two extra weeks of software development and driver practice.

We also practiced every day from 4PM until 8-9PM on weekdays, and 10AM-7PM on weekends. This robot put a lot of weight on the driveteam’s shoulders to run it at it’s limit. It also required perfect synchronization between the base driver and the operator. We also had the benefit of practicing against Team 1114, whom we shared a full practice facility with. So we practiced a lot, even on the day we left for the FIRST Championship.

It was SIMPLE, effective and WELL within our means to build. For perspective, this robot had only five motors. Any team could have built a robot like this that year, and with even a little practice they could have found themselves in the finals of most regionals they went to. While we did utilize a more expensive construction technique rather than simply sawing up and bolting together pieces of extrusion, the concept would easily carry over to any team.

I had the wonderful and rare opportunity to experience this entire season right in the trenches – from design, to manufacturing and humbly, driving. Because of the choices that this team made, we got to enjoy a trip to Einstein for their first time with two legendary teams who had each been there five times beforehand. It is something I will never forget.

We leave you with one simple thought to consider every build season: Before you start building a robot that does a 7 disc / 3 ball / 2 tube autonomous or has an arm with six degrees of freedom, ask yourself if you can get it done without harming the overall performance of the robot.

Article Content Provided by: Nick Lawrence (FRC1503 Alumni)

[…] PR Mentor: Cathy Schulz [EA] How to Pass Inspection [SA] Registration 2015: First 12 Hours [HL] Stop Overbuilding. Just Stop. [RP] Calling in an AIR Strike – FRC78 (2014) [PP] Coach’s Corner with Adam Freeman [SA] […]

[…] Nick Lawrence, a 1503 alumni, wrote a great piece on their 2011 season. Read more here. […]